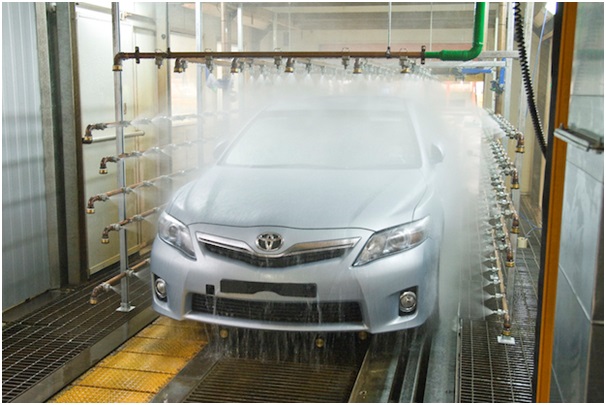

Quality vehicle manufacture requires the use of managed water deluge testing to certify the credentials of the vehicle’s build criteria. They are used extensively by vehicle manufacturers across the automotive, defence, commercial, mining and rail sectors and are a critical step in the quality assurance process. Water deluge testing systems are incorporated into production or testing lines and drench the vehicle with water, at a set flowrate and pressure

The design and construction of a state-of-the-art water deluge testing facility is surprisingly complex – more than just turning on a high pressure hose! There are a number of critical elements that need to be considered, including:

- Design elements to suit the specific size and shape of the vehicles to be tested.

- Consideration of the water flowrate and pressure for testing.

- Site constraints for the location of the testing facility.

- Integration with the existing or planned manufacturing processes.

- Technology and automation systems applied to managing and monitoring the testing and results, including user interfaces.

- Operator and site occupational health and safety to allow safe operation of the facility.

- Cost effectiveness with respect to water consumption and recycling.

- Design and construction approach to deliver timely and cost-effective commissioned facilities.

DRYSYS is the industry leader in the design, construction, installation and commissioning of sophisticated water deluge testing systems. DRYSYS offers a full turnkey solution, working closely with our clients to deliver the project from concept to commencement of testing. As a bespoke engineering firm, DRYSYS understands manufacturing processes and the importance of systems and process integration to ensure that the facilities we build work in closely with our clients’ existing manufacturing facilities.

At the nerve centre of our testing facilities is a surprisingly complex system that monitors a range of important parameters, including spray test waterflow rate and pressure, chemical dosing, water tank and sump pit storage levels.

This all requires a complex and intricate run of pipes, pumps, auto valves, sensors, filters and spray nozzles that are managed by a sophisticated PLC (programmable logic controls) system which provides the operator with a user-friendly interface and real time overview of the facility.

We offer unique solutions to our clients for water deluge facility design, construction and commissioning, which can include:

- Single point of contact for the duration of the project, so that the client does not have to engage multiple consultants and contractors.

- Automation and full remote control, minimising operational personnel and improving safety outcomes.

- Use of harvested rainwater and treated recycled water, resulting in significantly reduced water usage and costs.

- Modular structure and skid building techniques resulting in significantly reduced construction time and cost, and outstanding quality and safety outcomes.

DRYSYS is committed to partnering with our clients to deliver outstanding results from project conception through to turning the taps on. Our end-to-end, full service capacity means that our facilities are the best quality, delivered cost-effectively, safely and on-time.